Our Strengths

Competitive Manufacturing

Komatsu Management Principles

The cornerstone of Komatsu’s management principle is to commit ourselves to quality and reliability and maximize the total sum of trust given to us by all stakeholders and society, which it defines as corporate value. Maximizing trust requires corporate activities that are founded on social responsibility along with efforts to strengthen corporate governance and enhance competitive manufacturing. With the addition of Komatsu Brand Management into this principle, we are promoting awareness reforms that inspire all Komatsu Group employees to adopt the perspective of the customer from their standpoint in the Company as we move forward with human resource development to become a stronger company.

Competitive Manufacturing

We define competitive manufacturing as work not limited to people on the shop floor but as teamwork among all internal departments, such as R&D, production, sales and product support, as well as all value-chain partners, such as suppliers and distributors.

POINT 1Gemba (Workplace) Capability

We define workplace capability as the capability of each and every employee to improve his/her work spontaneously and continually. We have nurtured this workplace capability through TQM (Total Quality Management) over the years, thereby enhancing competitive manufacturing.

POINT 2Solid Partnership with Suppliers and Distributors

We conduct business as we team up with our suppliers and distributors in charge of sales and service activities by sharing values and principles. We have “Midori-kai”, the group of our suppliers in Japan, and regard it as the center of reinforcing collaboration. Midori-kai suppliers are asked to get involved in the development stage of products in order to enhance our product competitiveness. They are also invited to participate in our human resource development programs. We have also organized “Midori-kai” outside of Japan.

Strengths in Development and Production

We develop and produce key components, such as engines and hydraulic equipment, including the metal casting process, in Japan where we can capitalize on time-tested competitive manufacturing. In this way, we are well positioned to enhance our product competitiveness by reassessing all processes, including the design stage, when necessary. Further, we supply key components, which incorporate the world's top-level quality, cost and delivery advantages, to our assembly plants around the world.

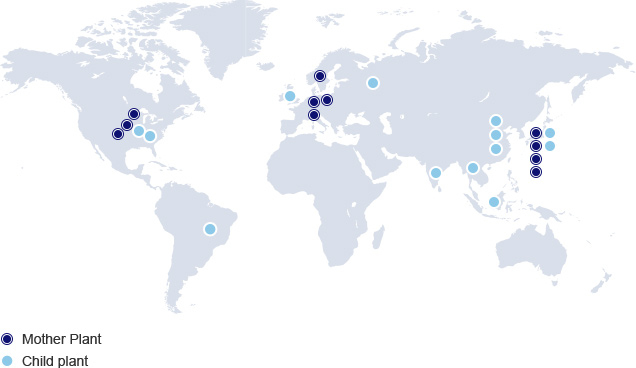

POINT 1Mother Plant System

We position assembly plants equipped with product development capability as Mother plants. When producing new products or making model changes, development and production divisions as well as suppliers team up to “build in” thorough quality, cost and delivery advantages. Mother plants are responsible for Safety, Legal compliance, Quality, Delivery and Cost of Child plants when producing the same models. In addition, Mother plants not only ensure the stable global supply of their products, but also work to transfer competitive manufacturing to Child plants.

Assembly Plants for Construction and Mining Equipment

Number of Production Bases by Region

| Region | Americas | Europe & CIS | Africa | Asia & Oceania | China | Japan | Total |

|---|---|---|---|---|---|---|---|

| Assembly |

11 |

10 |

1 |

5 |

4 |

6 |

37 |

| Components & parts |

24 |

8 |

1 |

7 |

5 |

7 |

52 |

| Materials |

1 |

0 |

0 |

2 |

2 |

1 |

6 |

| Total |

36 |

18 |

2 |

14 |

11 |

14 |

95 |

POINT 2Flexible Global Production

We assemble the equipment at the best possible plants, chosen especially by considering local market demand, foreign exchange rates and equalization of production load, and cross-sourced finished products around the world. Except for key components, parts with superior quality and low costs are supplied to assembly plants around the world from China and Southeast Asia.

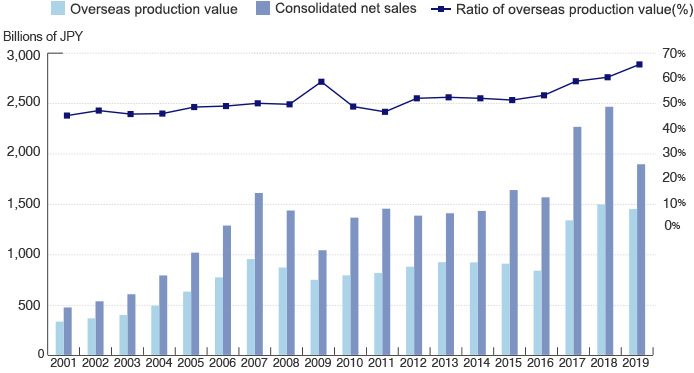

[Construction, Mining and Utility Equipment]

Consolidated Net Sales and Overseas Production Value

Strengths in Sales and Service

POINT 1Global Sales and Service Networks

Our network of 210 distributors in 148 countries covers 99% of the countries and regions with demand around the world. For mining equipment, Komatsu and its subsidiaries team up to engage in customer-tailored sales and service activities.

POINT 2ICT Applications: KOMTRAX

Komatsu has been setting the pace for implementing ICT applications in the construction and mining equipment industry. Concerning the use of all ICT-based information, we share it with our customers and distributors. Together we make customers' jobsite operations “visible” and improve their operations, thereby building up a solid relationship with customers. The number of KOMTRAX (Komatsu Machine Tracking System)-installed construction equipment has exceeded 560,000 worldwide, and we are utilizing a massive amount of information gained from the KOMTRAX in marketing and service operations. And as we promote SMARTCONSTRUCTION, we link entire workplaces through ICT organically to resolve construction workplace issues, such as those related to labor shortages and the aging of operators.

POINT 3Human Resource Development around the World

We are converging efforts to develop human resources globaly centering on 17 training centers in 14 countries. The training centers in Japan surpport centers all over the world as mother centers.

POINT 4Product Support Bases

Komatsu has established a global support operation capable of promptly providing parts. repaiirs, maintenance and the like in order not top stop machines at customer's jobsites.

| Parts centers (to distribute spare parts) |

45centens |

|---|---|

| Training centers (to train mechanics for skills) |

17centens |

| Reman/rebuild* centers (to repair and remanufacture engines and other key components) |

13centens |

- Reman/rebuild

Business to remanufacture or rebuild used components, such as engines and transmissions, to quality on par with new ones by exchanging or repairing worn-out parts.